Order up

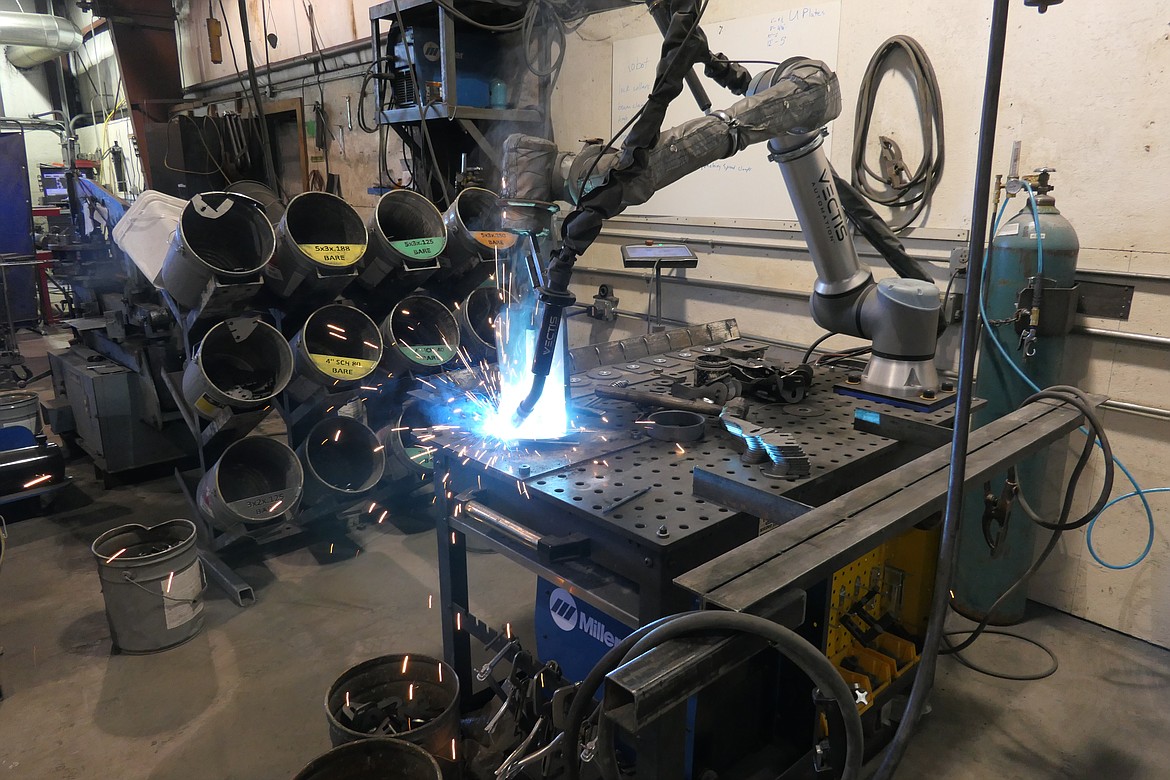

CHARLO — MT Solar, a small manufacturer in Charlo with a big reach, recently acquired a game-changing piece of robotics technology.

Company president and co-owner Travis Jordan said the crew was so excited when it arrived that they all started pulling off the shrink wrap, saying, “I wanna play...

Become a Subscriber!

You have read all of your free articles this month. Select a plan below to start your subscription today.

Already a subscriber? Login